by Mat Dirjish

Raytron, a provider of chips and terminals for industrial monitoring, smart manufacturing, and security, introduces its intelligent infrared (IR) monitoring system that combines IR sensors and AI algorithms. Poised to transform industrial monitoring, the system operates in high-temperature environments while providing continuous, non-contact monitoring and early detection of thermal anomalies before failures occur.

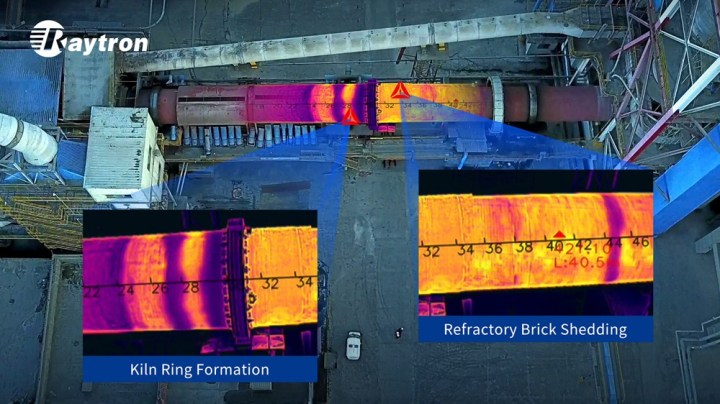

Synchronized Visible and Thermal Imaging for Online Rotary Kiln Monitoring

As per Raytron, every object above absolute zero emits IR radiation, capturable by IR sensors and translated into visualized thermal maps. In high-temperature environments, internal conditions are impossible to observe directly. Subtle shifts in surface temperature, however, often serve as the earliest indicators of internal failure. The system’s online thermal camera allows engineers to identify these hidden risks before a breakdown occurs.

Advantages of the company’s Industrial Thermal Imaging system include:

- Thermal imaging resolutions up to 1,200 x 600 deliver detailed temperature data across operating ranges from 0°C to 2,000°C, enabling precise analysis at the pixel level.

- Continuous thermal visualization that detects abnormal heat patterns without interrupting production.

- Custom monitoring zones and temperature thresholds trigger automatic alerts when detecting anomalies.

- Remote Monitoring enabling engineers to access live thermal images and temperature trend data from centralized control rooms.

For more details, visit the Raytron website.